|

Brazed Plate Heat Exchangers represent the most compact, rugged and cost-effective means of transferring heat in many industrial and refrigerant applications. Built from stainless steel with copper or nickel brazing materials, they provide exceptional corrosion resistance. They feature corrugated plates that produce highly turbulent flow in a true counter-current direction. This results in high efficiency and a very compact heat exchanger design. Due to the smaller size and reduced material content, they can be the most economical heat transfer choice.

Applications:

- Central Heating;

- Heating and Cooling in HVAC installations;

- Hydraulic and Lube Oil Coolers;

- Tap Water and Radiator Heating;

- Hydronic Heating;

- Geothermic and Solar Heating;

- Evaporation and Condensation in Refrigeration Systems;

- Heat Recovery;

- Steam Heating;

District or Zone Heating Systems |

|

|

The Outstanding Features:

- Compact structure and easy installation;

- Light in weight;

- Small consumption of water;

- Outstanding Overall Heat Transfer Coefficient;

- Wide Variety of plate sizes and Patterns;

- Durability and;

Low scaling coefficient. |

Because of the different material, the brazed plate heat exchangers have the following kinds

BHE |

Nickel brazed plate heat exchangers |

BHE |

Copper brazed plate heat exchangers |

Plate material |

AISI 316L |

Plate material |

AISI 316L/304 |

Connection material |

AISI 316L |

Connection material |

AISI 316L/304 |

Brazed material |

Nickel |

Brazed material |

Copper |

Max design temp |

150.C |

Max design temp |

250.C |

Min design temp |

–160.C |

Min design temp |

–160.C |

Max design pressure |

10 bar |

Max design pressure |

30bar,45 bar |

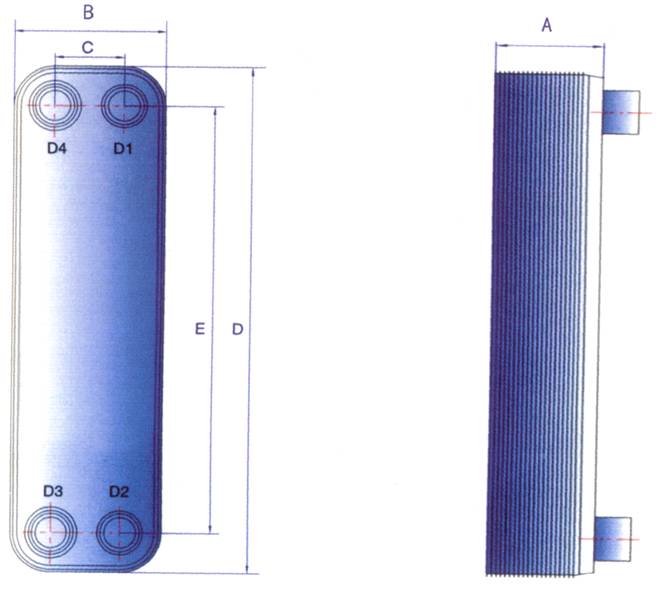

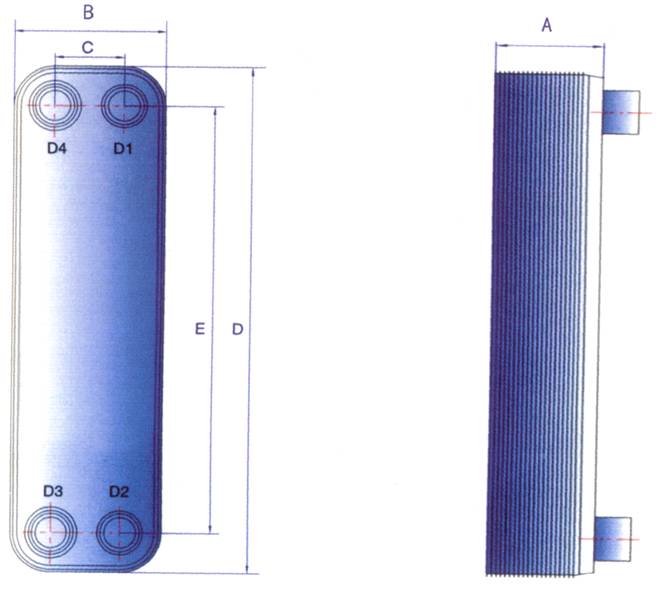

Brazed Plate Heat Exchanger Specification

Type |

A(mm) |

B(mm) |

C(mm) |

D(mm) |

E(mm) |

Weight(kg) |

Liquid Retardation Volume(Liter) |

Heat Exchanging area(m2) |

BL14 |

9+2.3N |

76 |

42 |

206 |

172 |

0.7+0.06N |

0.010(N-2) |

0.014(N-2) |

BL15 |

8+2.3N |

80 |

40 |

190 |

154 |

0.9+0.06N |

0.010(N-2) |

0.014(N-2) |

BL20 |

9+2.3N |

76 |

42 |

310 |

280 |

1.0+0.08N |

0.018(N-2) |

0.020(N-2) |

BL25 |

9+1.5N |

93 |

39 |

325 |

270 |

1.0+0.09N |

0.014(N-2) |

0.025(N-2) |

BL26 |

9+2.4N |

111 |

50 |

310 |

250 |

1.3+0.13N |

0.025(N-2) |

0.026(N-2) |

BL50 |

9+2.4N |

111 |

50 |

525 |

466 |

2.0+0.23N |

0.047(N-2) |

0.050(N-2) |

BL95A |

11+2.4N |

191 |

92 |

616 |

519 |

7.8+0.44N |

0.105(N-2) |

0.095(N-2) |

BL95B |

11+2.8N |

191 |

92 |

616 |

519 |

7.8+0.44N |

0.125(N-2) |

0.095(N-2) |

BL100 |

9+2.2N |

248 |

157 |

496 |

405 |

6.5+0.386N |

0.08(N-2) |

0.1(N-2) |

BL200 |

13+2.7N |

321 |

188 |

738 |

603 |

13+0.8N |

0.220 (N-2) |

0.210(N-2) |

BL250 |

13+2.8N |

363 |

232 |

798 |

655.7 |

13.5+0.97N |

0.240(N-2) |

0.260(N-2) |

Note: N indicated quantity of plate

|